Hot Wire Cutter

- Timothy Bukowski

- Dec 12, 2018

- 2 min read

Updated: May 8, 2020

February 2020

Overview

For this project I worked in a team of 4 to create a hot wire cutter which is used to melt plastic or cut through foam. It is a simply functioning device which runs current through the nichrome wire has a high resistance and heats up.

Objectives

Create a functional and comfortable design

Become familiar to with the 3D printing process

Learn the DFM involved in 3D printing

Preliminary Designs

Design Considerations: Essentially had two shapes to choose between. Decided on the straight version as it was more versatile and allowed the hot wire to be held like a pencil for detailed cuts, but also held like a hammer for longer and thicker cuts.

Final Prototype Design

Features:

Round, long body to feel similar to a pen

Wire with sharp corned for detailed cuts and flat end for bigger cuts

Flat top for comfort in the hand, and to make parts fit together better

Fastened using rings- very simple assembly for 3D printed prototype

Clay insulation around nichrome wire

Momentary switch - safe way to ensure that wire is only hot when the switch is pressed

Construction

Issues:

Printing proved to be the most problematic part of making our design. First we found the the print to have much smaller dimensions on the holes, warping along the length and the surface was also very rough as you can see in the red part in the slides above. We adjusted the hold dimensions and tried to fill in the case to prevent warping, but found that it made the warping worse. After playing with the supports and the orientation of the print we were able to get a good prototype.

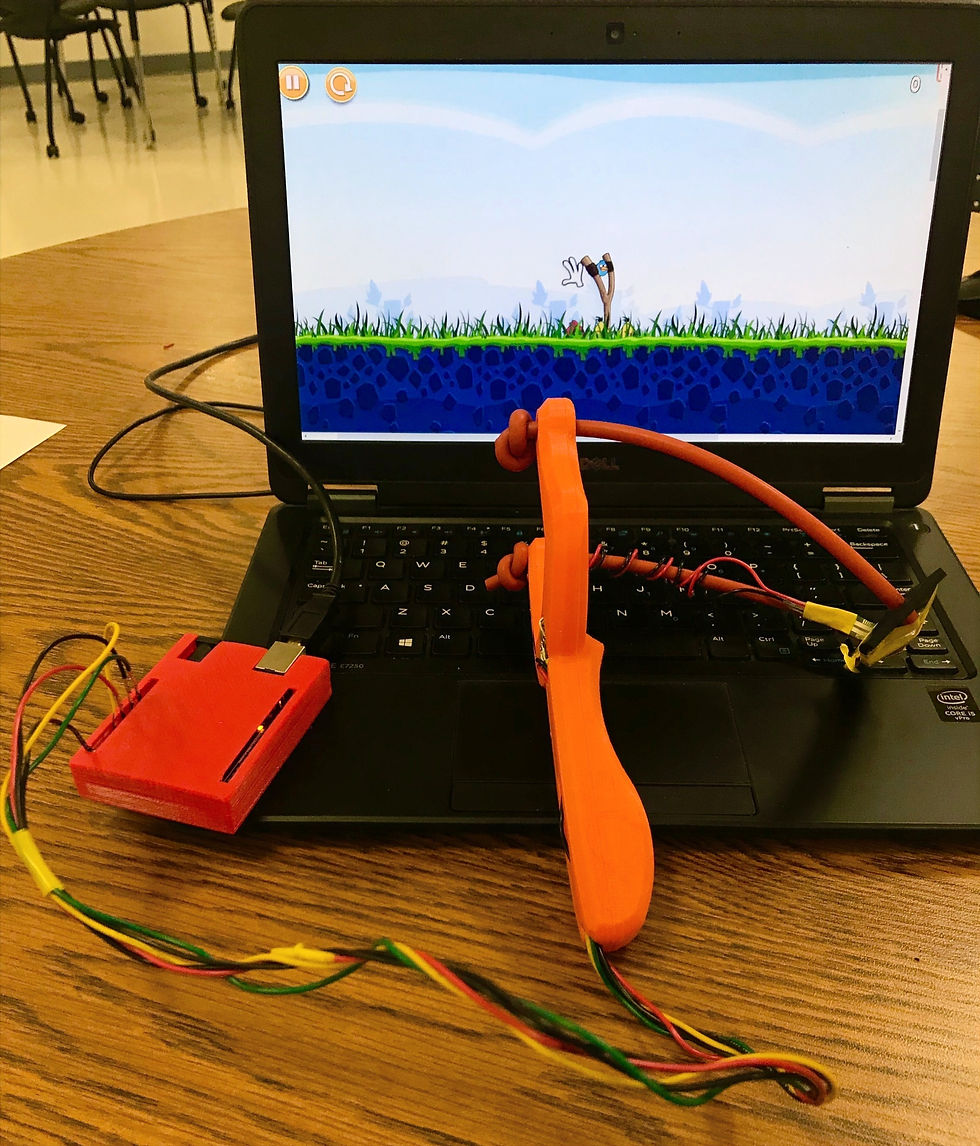

Finished Prototype

Final Comments:

We ended up not using the third ring in the middle because we found it to be uncomfortable and unnecessary. We found it to be comfortable to use in both positions shown above and its symmetrical shape allows both right and left handed comfort. In the future I would create a more ergonomic design and make the insulation smaller, allowing for a smaller and more comfortable shape. I would also create the handle with a different process like injection molding to create a smoother grip with more accurate dimensions.

Comments